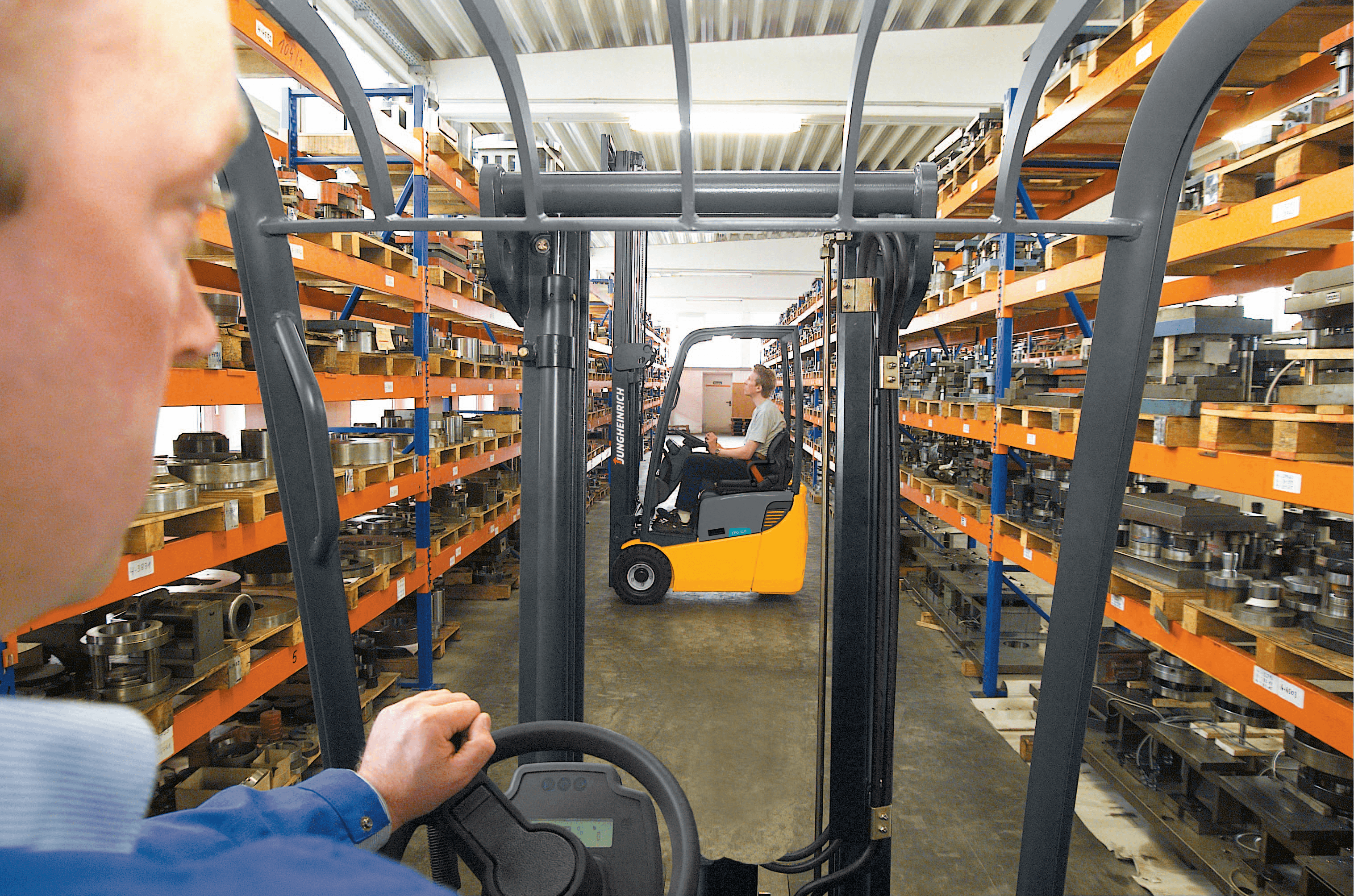

Safety Above All

Forklifts play a vital role in keeping businesses moving – from transporting products to operating in heavy-duty outdoor applications. These are a few simple lift truck operation guidelines to help keep your operators and your workplace productive and safe.

Lift Truck Operation Best Practices

- Always use the lift truck’s operator seat belt or restraint system.

- Stay inside the operator compartment, and never reach into moving parts of the truck.

- Obey all company safety tiles and posted traffic signs – including speed limits.

- Keep a clear view of the path of travel.

- Start, stop and change directions smoothly.

- Sound the horn and slow down when approaching intersections, blind corners, door and ramp openings, pedestrians and other vehicles, and when backing up.

- When traveling, keep the forks in a low position that provides adequate clearance over the surfaces you will travel.

- Maintain a safe distance from the edge of docks.

- Never jump on or off a stationary or moving lift truck.

- Operators should always wear the required protective clothing and equipment for your application, such as steel-toed shoes and safety vest.

- Ensure all operators are properly trained and certified to operate a lift truck.

Are your employees required to have a license to operate a lift truck?

Attend a formal OSHA certified lift truck operator training class to receive the answer.

• How often should a lift truck be inspected?

• How much does your lift truck weigh when sitting empty?

• Do you know what can happen when the lift truck’s center of gravity moves outside its stability triangle?

• How often should lift truck operators be trained?

Do you want to educate your operators in all areas of safety training?

After taking an Operator Safety Training Course, operators will know:

• The characteristic of a professional operator

• How to identify key components and their functions

• The information contained on vehicle capacity plates & how they affect operation

• Safe operating procedures when traveling, handling loads and working in aisles

• The appropriate action in case of a tip over

• How to perform a pre-operational walk around inspection

• The importance of studying the lift truck’s operator manual

We bring the training directly to you and your associates, saving you time and money.

Benefits of our Lift Truck Operator Safety Training Course:

• Our trainer comes to your operation at no extra charge

• We use your facility and equipment to enable more employees participate in the training program and not have to shut down your operation.

• Your employees will feel more at ease and will be able to retain more of the training if they are in a familiar territory.

• All trainers are certified by the state and

by Caterpillar/Mitsubishi

• Our training class includes on-site and equipment-specific training and observations.

Training Manager: patrick.knisel@ringpower.com | 407.375.4551